Heritage Creative from Heritage Church in Sterling Heights, MI brings us these huge letters on their stage. (originally posted October 2016)

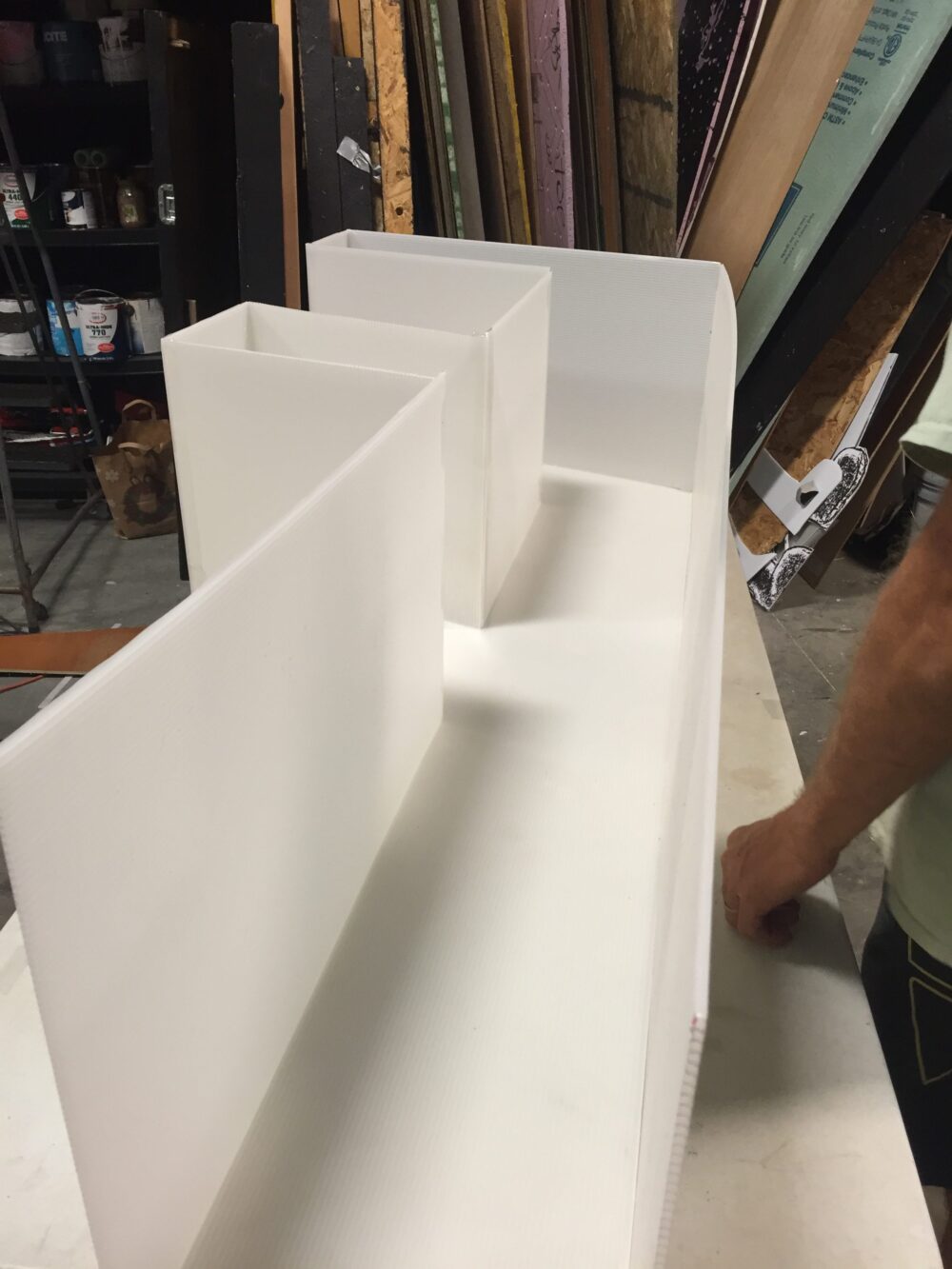

From the team: For our “Daring Faith” series, we wanted to take the font on the marketing material and turn it into giant 3D letters for our stage. We took the exact font used for the series design and printed it out on our plotter (5 ft 6 in. high). We then cut each letter out and traced them onto 4X8 sheets of corrugated plastic (5MM/Natural/translucent). Each corrugated plastic letter was cut out using a utility knife and a straight edge. We then traced the corrugated letter onto a backing of scrap luan or 1/2 foam (leftover scraps from previous sets). The quality of the back piece did not matter as it would not be seen. The backing was then also cut out. Then we cut many lengths of 16-inch by 8ft strips of corrugated to be used for the sides of each letter. Every cut was square (this made it quick and easy). We simply cut the sides to match the face piece. Where we had curves in letters such as “D”, we simply cut many 1-inch cuts 1/2 way through the thickness of the corrugated, then snapped it so that it would bend around the face of the letter. Everything was taped together using packing tape. We took extra care to be sure to have the front face clean. The sides were taped behind the front face so that there was no open corrugated exposed. We also took care to be sure there were no gaps as light would escape if there were. Once the front face and sides were built, we added 16-foot LED strips with duck tape to the center part of the back of each letter. Each letter had its own LED tape and controller: https://www.amazon.com/dp/B00B42M3RG/ref=as_li_ss_tl?ref_=pe_621110_204385130_shiptrack_e_304_dt_1&linkCode=sl1&tag=csdi-20&linkId=f802244b84953e244755355b08976955

Note: The LED strips don’t work on DMX without these: https://www.amazon.com/dp/B00B42M3RG/ref=as_li_ss_tl?ref_=pe_621110_204385130_shiptrack_e_304_dt_1&linkCode=sl1&tag=csdi-20&linkId=f802244b84953e244755355b08976955.

Our lighting genius’ had to do some re-wiring. Because each letter had its own LED strip and box, each letter can be a different color and can chase (See link below at 3:18). Finally we attached the backs (with the light strips) to the front and side faces using the packing tape and placed them on the stage on a small riser. The bold letters stand on their own, however “FAITH” was screwed into thin strips of wood that hand down from a wood frame we have on our stage against the curtains. Otherwise, they would tip over. Finished it up with light bars along the risers under the letters.

Corrugated plastic: $12 per sheet

Tape: $25

LED strips: $15 each (a re-usable investment)

LED controller: $22 each (a re-usable investment)

Have to say it….but in the video the crowd looks “real” interested in your MASH-up..

I go to Heritage, and I notice that too; it is quite weird. When the singer asks people to stand and sing, nearly everyone does. When the singer says please stay seated and listen, everyone does… When people talk after service, they are complimentary, although I’m sure not everyone enjoys everything we do, but most people say they like it… We’ve actually brainstormed about this. What can we say when we want people to not stand and sing along, but we don’t want you to feel like you have to sit totally still? I am used to pop concerts. Even if you’re sitting, you can still “dance” and groove. Maybe church people are more used to classical concerts. I dunno.

Like this design a lot. I wish we had a plotter, tracing via a projector isn’t my favorite.

This also seems a lot sturdier than the other big 3D words made out of coroplast one on this site which also makes it easier to make in the long run.

Where did you get natural coroplast for $12/sheet without buying a whole pallet worth of coroplast? Also, when you say “luwon” do you mean luan plywood? Thanks so much for your contribution.

Yeah, luan, oopsie.

There is a plastic distributor in southeast Michigan called Laird plastics. They are our supplier for the corrugated. We probably found them by searching online and calling around–I really don’t remember.

I was extremely impressed with how sturdy they are. When the boss said she wanted 3D italics lit from the inside, we all said she was nuts. But it worked, and it was surprisingly straightforward to build. Most of our sets are days of trial-and-error followed by weekly fixing, but this one worked first try, and has stayed up (which is great because it is an 8-week series).

:-)

I think the other thing that helped the rigidity was paying attention to the “grain” of the corrugated. We plotted them so that they would fit exactly on one sheet width so we could keep the corrugations as vertical as possible.